Steven Hill Glaze Workshop - Results from workshop held at Standard Ceramic on November 19-21, 2010 "Throwing, Spraying, and Electric Firing".

A three day workshop sponsored by Standard Ceramic was conducted at Standard's facility in Carnegie, PA. The first day was devoted to throwing demonstrations by Steven and the pieces produced were force-dried to make them ready for single firing in electric kilns

Throwing demo.

Throwing small porcelain cup.

More throwing.

Drying rim of bowl.

Adding spout to pitcher.

Adding handle.

Participants ready for spraying demo. Standard constructed one spray booth for each glaze.

Standard also provided an effective exhaust system.

Samples of suggested glaze combinations. Steven supplied most of the glazes but some participants brought their own. These were Cone 6 glazes.

Steven demonstrating his glaze spraying techniques onto his greenware pitcher.

Notice the use of safety mask.

Receiving advice.

Participants at work.

Waiting in masked silence.

Participants moved from station to station, selecting their own glaze combinations.

More glazing.

Participants' ware cooling on the last day.

Pots in a different kiln.

A third kiln. Believe there were four kilns in all.

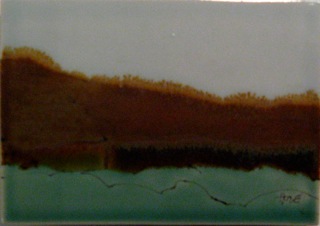

Participant result.

Another finished pot. Participants brought three bisque pieces each.

Feedback from participants was that they were pleased with the results, especially with glazes and techniques that many had not used before.

Learning the properties of each glaze and the thickness to apply and in what order requires attention to detail and note-taking.

Showing a number of glaze combinations.

Bisque tiles were used under the pots to protect the shelves from runny glazes.

That green glaze sure did run.

More participants' work.

Many thanks to Steven Hill for conducting the workshop and sharing these techniques. Also, much credit to Standard Ceramic Inc. and its employees for all the preparations required for a successful workshop. Finally, thanks to Linda Dujmic, Carla Flati, and Lisa Sittig for photos and descriptive information.

www.stevenhillpottery.com

www.standardceramic.com

Questions answered by Linda Dujmic, workshop participant.

When Steven was spraying, what tips did he provide for better results? He explained how to use the spray guns and add more glaze.

What was your experience in spraying? It wasn’t difficult.

How did you measure thickness? It was a problem to estimate the amount of glaze needed. You have to have a feel for when there is enough glaze on a piece and this only comes with experience. Since we were inexperienced, we tended to get more glaze on a piece than we needed and a lot of glaze ran during the firing. You can’t expect great results the first time, especially in a workshop environment.

If you had the equipment in you studio, how much would the workshop be helpful in actually doing it or would you say that you now know that it could be done but you would need to invest considerable time in learning what glaze combinations to use? The workshop was helpful in that I was able to try a new glaze technique and as with all glaze application. It would take some time to get comfortable enough with it to get the results that I personally wanted. I consider the workshop a stepping stone that I can use to generate new ideas for my own style and technique.

Another finished pot. Participants brought three bisque pieces each.

Feedback from participants was that they were pleased with the results, especially with glazes and techniques that many had not used before.

Learning the properties of each glaze and the thickness to apply and in what order requires attention to detail and note-taking.

Showing a number of glaze combinations.

Bisque tiles were used under the pots to protect the shelves from runny glazes.

That green glaze sure did run.

More participants' work.

Many thanks to Steven Hill for conducting the workshop and sharing these techniques. Also, much credit to Standard Ceramic Inc. and its employees for all the preparations required for a successful workshop. Finally, thanks to Linda Dujmic, Carla Flati, and Lisa Sittig for photos and descriptive information.

www.stevenhillpottery.com

www.standardceramic.com

Questions answered by Linda Dujmic, workshop participant.

What you learned by watching him throw? I learned his throwing style. Everyone throws differently and has their own little tricks and he wanted to show us how he achieved the effects he wanted.

What was his purpose in having you sit and watch him throw? I don’t really know. I guess to give us an idea of where he was coming from.

Was the throwing so he could generate work for spraying and that was his primary purpose? I think he wanted to share his style with us and to generate some greenware pots to demonstrate his spraying techniques.

In general, could you describe his theory for layering glazes? To get the effects of a gas firing.

Why this one over another? This is the way he liked the glazes. He only gave us suggestions. We were free to experiment with different glaze layering and most of us did do this. One person even used their own glazes instead of his.

Did he say that he tested the glazes in various combinations to see the results and that anyone replicating that would have to do the same? I don’t remember his saying this but obviously, anyone would have to experiment with different combinations of whatever glaze they used to get something that they personally liked.

In general, could you describe his theory for layering glazes? To get the effects of a gas firing.

Why this one over another? This is the way he liked the glazes. He only gave us suggestions. We were free to experiment with different glaze layering and most of us did do this. One person even used their own glazes instead of his.

Did he say that he tested the glazes in various combinations to see the results and that anyone replicating that would have to do the same? I don’t remember his saying this but obviously, anyone would have to experiment with different combinations of whatever glaze they used to get something that they personally liked.

When Steven was spraying, what tips did he provide for better results? He explained how to use the spray guns and add more glaze.

What was your experience in spraying? It wasn’t difficult.

How did you measure thickness? It was a problem to estimate the amount of glaze needed. You have to have a feel for when there is enough glaze on a piece and this only comes with experience. Since we were inexperienced, we tended to get more glaze on a piece than we needed and a lot of glaze ran during the firing. You can’t expect great results the first time, especially in a workshop environment.

If you had the equipment in you studio, how much would the workshop be helpful in actually doing it or would you say that you now know that it could be done but you would need to invest considerable time in learning what glaze combinations to use? The workshop was helpful in that I was able to try a new glaze technique and as with all glaze application. It would take some time to get comfortable enough with it to get the results that I personally wanted. I consider the workshop a stepping stone that I can use to generate new ideas for my own style and technique.